Overview

Purpose

The MIL-STD-461 CE102 test method defines how to measure conducted emission noise on the power leads of electric units. Unlike FCC testing which only applies to AC power inputs, CE102 applies to both AC and DC power inputs. The purpose of this testing is to ensure a high quality of the power supplied by the bus and limit the noise seen by connected units. Also, because power lines are usually unshielded, it limits the amount of electric field coupling to nearby sensitive analog circuits.

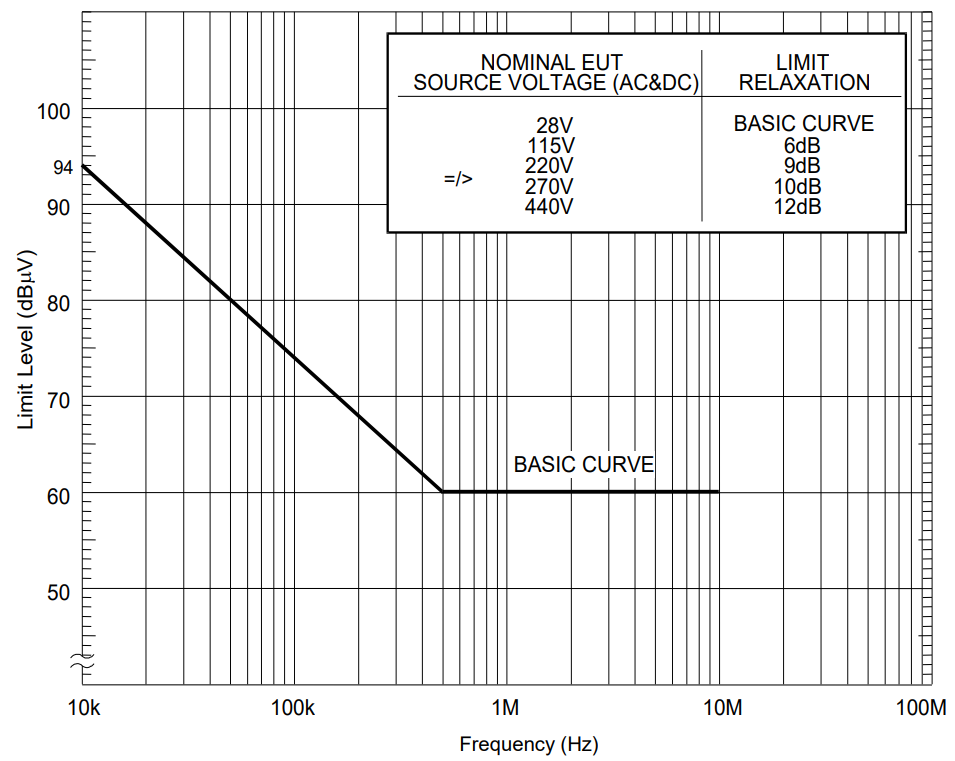

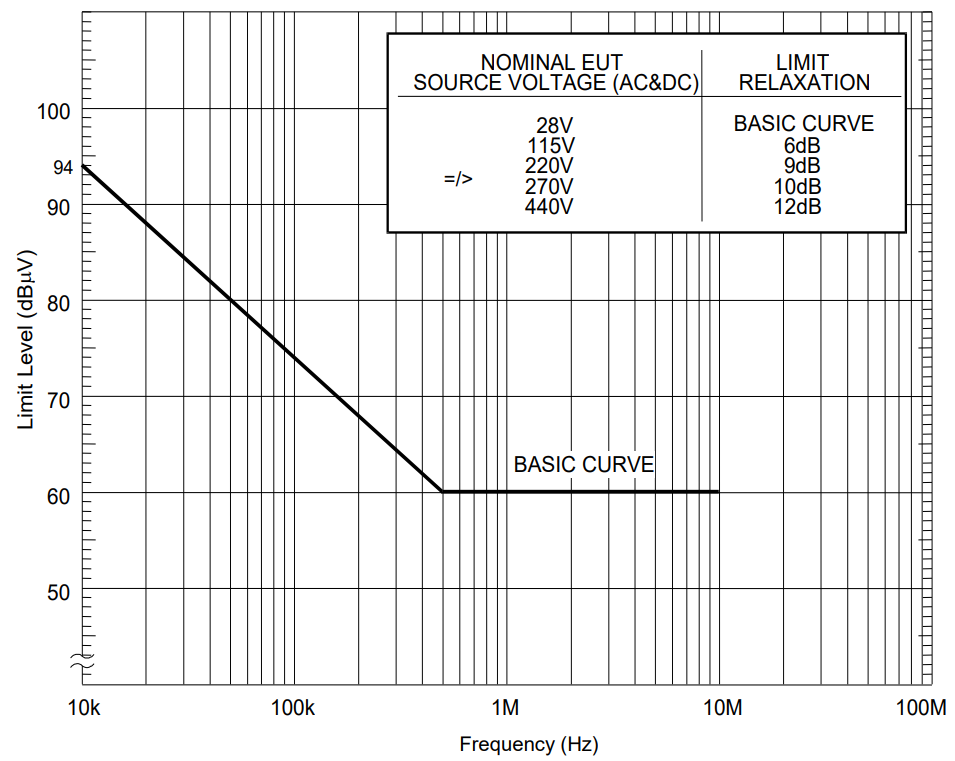

CE102 Limit Line

The standard CE102 limit line for AC and DC powered units when tested with a 50 µH LISN is shown below and defined for noise from 10 kHz to 10 MHz. For comparison, FCC testing requires conducted emissions testing from 150 kHz to 30 MHz. Several tailored versions of space satellite EMC requirements extend the 60 dBµV limit line out to 20 or 50 MHz. I recommend performing pre-compliance EMC testing to at least 30 MHz to ensure your product is designed to meet multiple applications. Note that all limit levels are RMS so 60 dBµV = 1 mVrms = 1.414 mVpk.

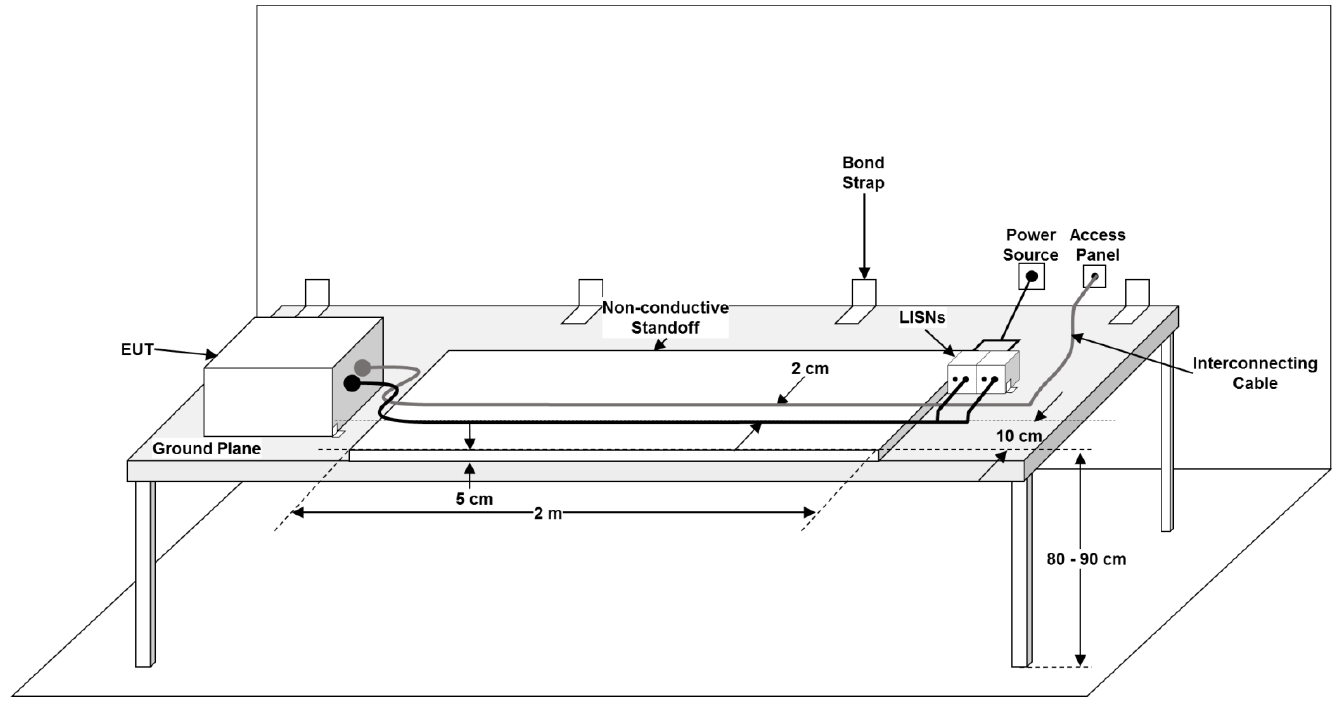

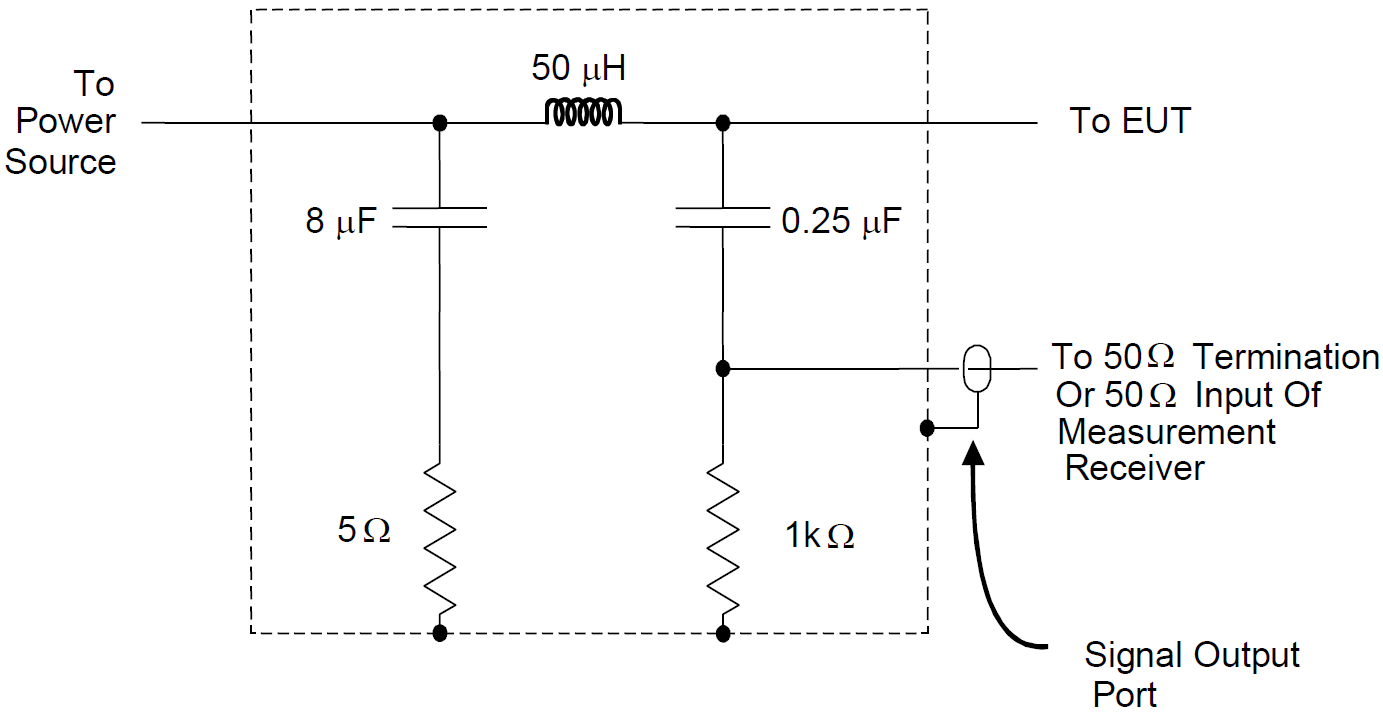

CE102 Test Setup

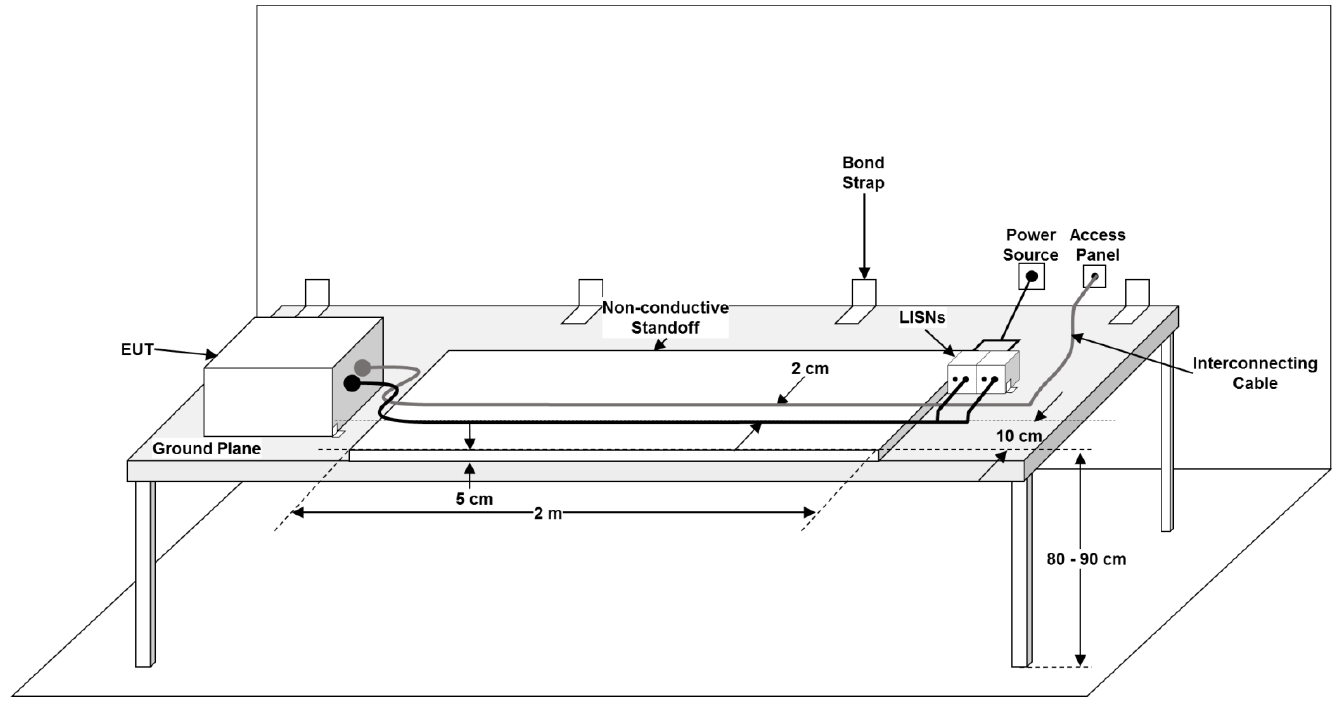

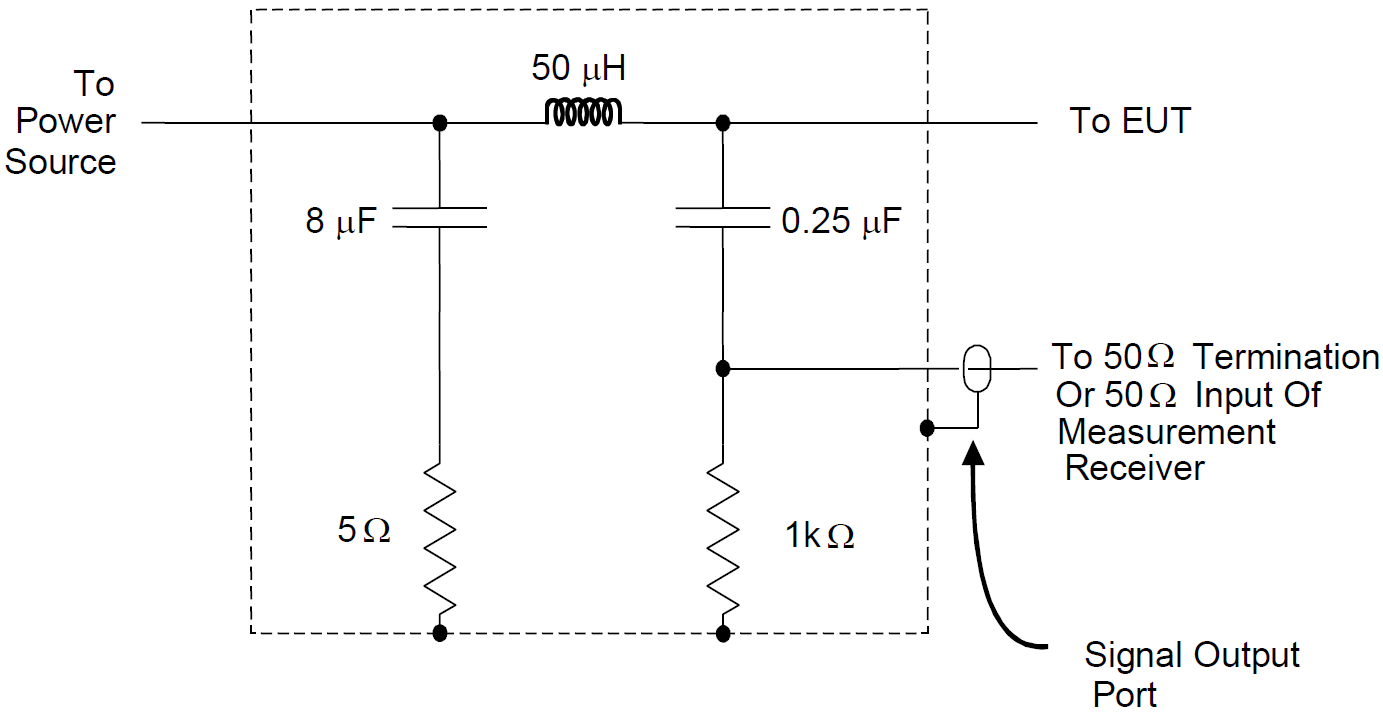

The diagrams of the general test setup, the CE102 measurement setup, and the 50 µH LISN schematic are shown below. These detail how the cables should be laid out and how the LISN should be connected. Note that to meet this setup the test harnesses need to be 3 meters long minimum. Also, this setup explicitly assumes that power and communication lines will go to separate connectors and will have a minimum separation of 2 cm. Space satellite electronics oftentimes try to bundle the power and high-speed communication interfaces in the same connector and cable bundle which can cause noise coupling problems in this testing. Also note that some space standards require testing with a 5 µH LISN which is more representative of the relatively short spacecraft harnesses. The "measurement receiver" called out in this diagram usually refers to a spectrum analyzer but oscilloscopes can be used in pre-compliance testing.

Design and Analysis

General Approach

Compliance to CE102 can be achieved using a combination of simulation and pre-compliance bench testing of a prototype. This section will cover some considerations in the steps involved.

CE102 Simulations

For simulations I typically use PSpice because it is easy to use and can use the manufacturer component models. I recommend building up a CE102 simulation in a few steps:

- 1. Generate a source model.

The primary source of power line noise will be the input switch converter. This is often a flyback converter due to input power isolation requirements. The source model should be constructed with the transformer, the FET switch and any snubber circuits used. For accurate modeling parasitic must be used including the drain to source capacitance of the switch, the capacitance from the primary to secondary winding on the transformer, and the leakage inductance on the transformer primary side. The output load can usually be modeled as a resistor, but care should be taken with the grounding.

This step is often the most difficult and time consuming but also the most important!

- 2. Add input power, LISN and connecting cables.

The input power supply and LISN should be added to the simulation model. Ideal linear component models are usually fine for the LISN components because the impedance of the LISN is carefully checked and confirmed with measurement. The connecting cable is 2 meters long and can have a significant effect on the results if neglected. I recommend modeling this cable as a lumped element multiconductor transmission line.

- 3. Add the filter components.

Finally, the components making up the input filter should be added to the simulation. This includes any line to ground (Y rated) and line to return (X rated) capacitors and any inductors. These capacitors must include the parasitic inductance and resistance and accurate models can be taken from the device manufacturer websites. Common mode chokes and inductors models should be taken from the manufacturer website if available or approximated from datasheet specifications. Nonlinear effects such as DC bias voltage dependency of ceramic capacitors and saturation of inductors.

Care should be taken in this step because component accuracy will dominate the simulation accuracy.

- 4. Perform the simulation.

The PSpice simulation should be performed in the time domain with the minimum step size set based on the maximum frequency. The data points should be ignored until after the simulation has settled to steady state behavior. The maximum simulation time should be set to between 0.1 and 1 ms to cover the minimum frequency response but the time should be selected should be an integer number of switching cycles to prevent FFT errors.

- 5. Post processing.

The LISN line and return port voltage should be probed in the simulation and an FFT performed in PSpice. The FFT should be exported to a CSV file format and then opened in Excel. The data should then be plotted with a script or a CS102 Excel template. This will plot both the line and return LISN noise vs the CE102 limit line and calculate the design margin.

For most simulations I recommend a minimum design margin of 20 dB to account for the uncertainties of the models used.

CE102 Pre-Compliance Testing

It is critical that a prototype of the design be tested as early as possible. This will validate the simulation and give good confidence in passing the formal EMC qualification testing. If you chose not to perform a simulation of the CE102 noise, then this pre-compliance testing is even more critical.

Here are some tips on pre-compliance EMC testing that I've learned over the years:

- 1. Get or make a LISN.

Many affordable LISNs are available, and I highly recommend buying a couple. You will need at least two, one for the input line and one for the power return. If you can't buy the LISNs due to budget or procurement restrictions, then make your own. Be sure to select components that do not have resonances in your measurement frequency. LISNs are among the easiest EMC instruments to design and make at reasonable current levels.

Not having a LISN is no excuse to skip conducted emissions testing!

- 2. Get a ground plane.

The equipment under test and cables should be placed on top of a ground plane. This is important to keep the grounding representative of the final testing and helps reduce nearby RF noise from coupling on the cables. If you don't have a metal table, then get a roll of aluminum skirting or sheet metal from a hardware store and lay it out on a wooden table.

- 3. Use an oscilloscope.

If you have a spectrum analyzer then feel free to use it. However, those can be hard to find, and an oscilloscope can give similar results. Oscilloscopes also have a built-in math function that can calculate the common mode and differential mode noise directly. Keep in mind that the oscilloscope channel must be 50 Ohm terminated and the noise floor will be higher than a spectrum analyzer. With either measurement device the peak maximum should be used, not an average or quasi-average as allowed in FCC or CISPR testing.

- 4. Check your power supply input.

Sometimes a lot of noise is seen due to a low-quality external power supply. A LISN will provide some filtering, but often more is needed. Check for this problem by replacing the EUT with a resistor. If the noise remains, then add additional filtering between the external power supply and the LISN. Identifying and fixing problems like this is much easier on the bench than at the EMC test lab.

Remember, we are testing the EUT for compatibility to CE102 and not the external power supply.

- 5. Use an isolation transformer to prevent the GFCI from tripping.

When connecting to an external AC power supply it may be connected to a ground fault circuit interrupter (GFCI). The current through the LISN capacitors to ground are enough to trip any GFCI. To prevent this problem an isolation transformer should be used. This will isolate the line and neutral conductors from the circuit to prevent those common mode currents. The ground connection must be maintained and the neutral on the secondary side should be bonded to ground as required by the National Electric Code (NEC) Article 250.

The grounding requirements of the NEC must be followed for safety!

- 6. Post processing.

The data from the bench testing should be plotted and compared to the simulation data. If failures occur, then go back and update the simulation model to identify the discrepancy. I recommend having at least 10 dB design margin at bench testing before going forward with qual testing. This extra margin is needed to account for setup and instrumentation differences between pre-compliance bench testing and the full MIL-STD-461 CE102 setup.

Need Help?

If the steps above seem daunting or you run into problems along the way, then please reach out to EMI Sleuth for help in closing the analysis and getting the unit passing.