The MIL-STD-461 RE102 test method defines how to measure radiated emission noise from electric units AND their electrical cables. Most people believe that EMI come from the unit itself, but most radiated emissions failures are due to currents on the cables which are excellent radiators. It is extreamly important to document the shielding requirements of your unit cables and to test how you fly.

The RE102 test has similarities to the automotive test method CISPR 25 but is significantly different from the general commercial testing standards including ANSI C63.4 and CISPR 32.

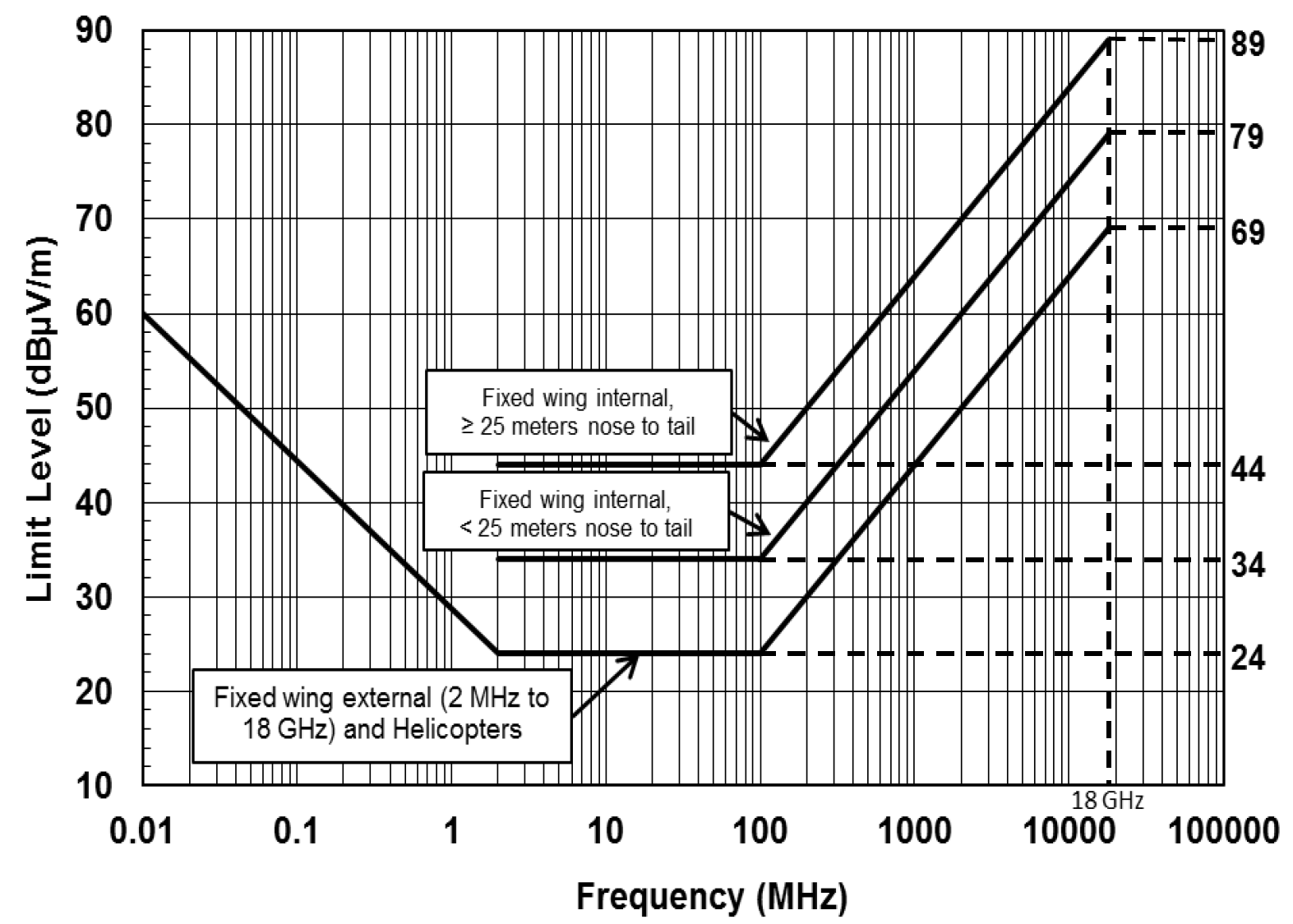

The standard RE102 limit line for aircraft and spacecraft applications from 10 kHz to 18 GHz is shown below when tested at 1 meter from the setup. For comparison, FCC testing requires conducted emissions testing from 30 MHz to a maximum of 40 GHz with distances of 3 meters and 10 meters. The limit is given as dBμV/m which is calculated from the linear electric field as 20*log10(E[μV/m]/1[μV/m]).

Keep in mind, the standard limits given in MIL-STD-461G are just a starting point and most programs require tailoring of the RE102 limits following MIL-STD-464 and it is very common to include receive band notches. Receive band notches for the lower GNSS band (1164 MHz to 1300 MHz), upper GNSS band (1559 to 1610 MHz), and S-band communications at 2200 to 2400 MHz are common. Whether the unit is placed inside the satellite faraday cage will affect the required RE102 limit for these receive band notches, but the notches generally range from 30 to 50 dBμV/m. A common practice for spacecraft EMC designers is to set a flat limit of 70 or 80 dBμV/m across the 10 kHz to 18 GHz range and add the receive band notches.

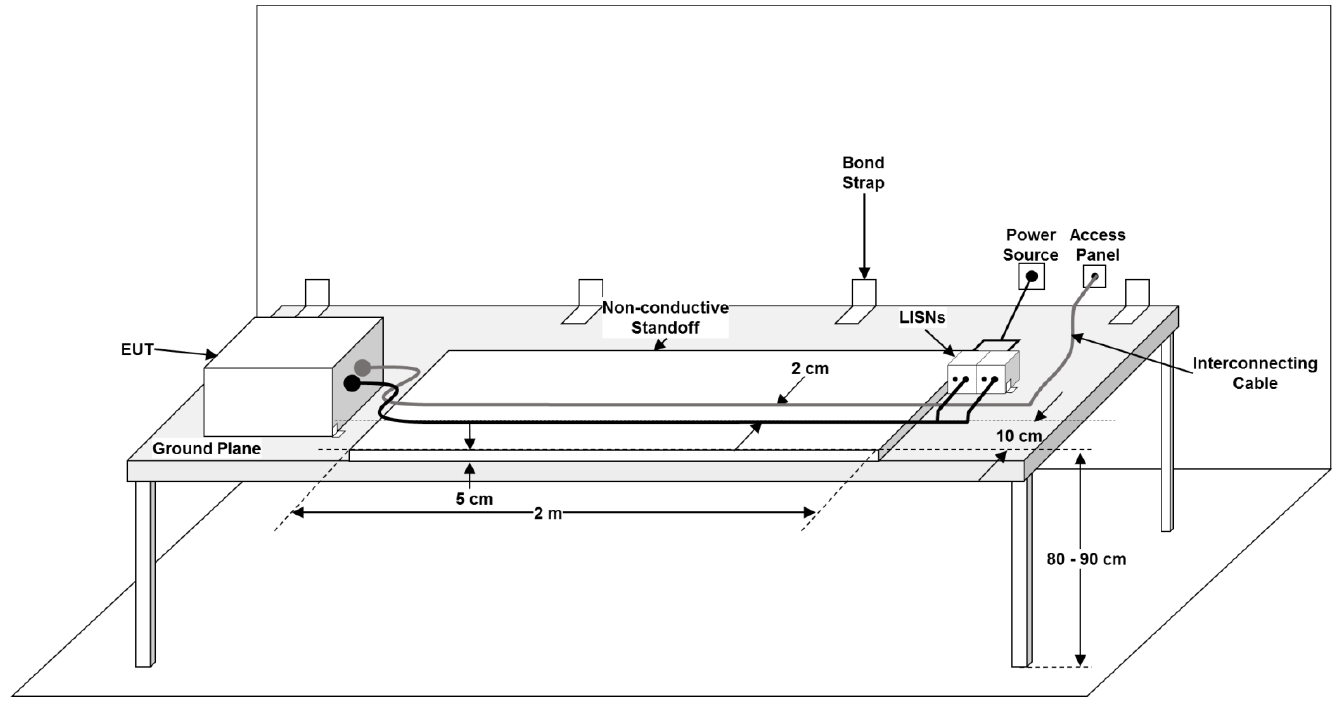

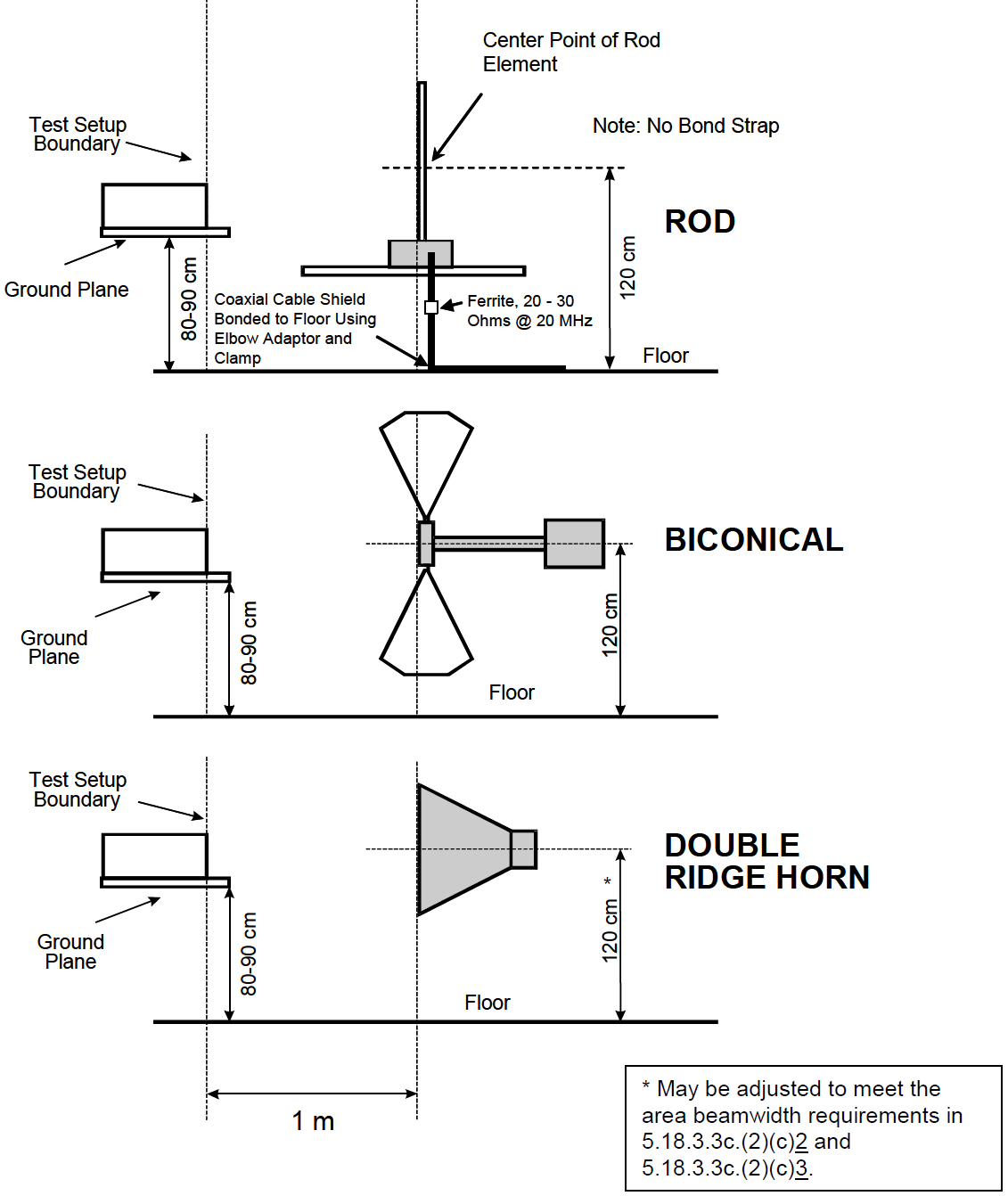

The diagrams of the general test setup and the RE102 antenna positioning is shown below. This is similar to the CE102 setup except that the LISN measurements ports are terminated.

The standard RE102 setup shown above assumes that power will be unshielded and that the power and communication signals will be routed seperately but this is often not the case for 28 VDC applications where the power and communications are often routed together inside an overbraid shield. If your have a shielded harness and break out the power to the LISN, then the shield will be broken and RF currents allowed to penetrate the shield barrier. In this case, it is best to route the harnesses through the chamber bulkhead connector and terminate the power leads to a LISN outside the test chamber. This will maintian the overbraid shield and prevent RF currents to penetrate the shield barrier.

Compliance to RE102 can be achieved using a combination of simulation and pre-compliance bench testing of a prototype. This section will cover some considerations in the steps involved.

For simulations I perform radiated emission estimations in several steps. Each subsequent step will increase the accuracy of the emissions model. When simulations are required, I prefer to use circuit simulations with PSpice because they give deep understanding of the emissions and can be performed much faster than a full 3D electromagnetic solver.

The Goal: Identify likely emission sources and their frequencies.

The Goal: Identify where the currents can flow from a big picture view. This can help us spot obvious problems early on.

The Goal:Quantifying the radiated emissions from the cables. This will help identify if additional filtering or shielding is required.

The Goal: Quantify the emissions to determine what enclosure shielding is needed and how much.

The radiation emissions simulation method described above assumes you are following good practices for PCB design. Specifically, the loop area formed by the return current path must be minimized. Be generous with adding stitching vias, especially when signal traces change layers.

Avoid split ground planes because they will usually form unintentionally large radiation loop areas with the current return paths. Split ground planes can also make great patch antennas so the risk of unintentionally radiating high frequency harmonics of the clocking signals is significant. The technique of using split ground planes was more common when electronics were slower, but they are a band-aid solution that does more harm than good with modern high-speed electronics. Some older op amp datasheets recommend a split ground plane but most modern, and especially high speed, op amps recommend a solid ground plane.

Partitioning circuits by type (power, digital, analog) is always more effective at reducing noise coupling than attempting split ground planes. Applications that cannot tolerate a solid shared ground plane should already be using isolation circuits (i.e. digital isolators or optocouplers) to reduce coupling.

Testing your product before taking it to the lab for official EMC testing is the key to passing the first time. The EMC simulation discussed earlier can be useful in identifying risks early on, but these models are simplified and need to be validated with bench testing.

The hardest part of pre-compliance testing is controlling noise pickup from the environment. Ideally you will have a shielded room to test in, but that is not feasible for a lot of companies. Portable fabric EMI test chambers are a good option and can typically give 40 to 80 dB of shielding but can be expensive. Here are my recommendations for pre-compliance testing for RE102 outside of a shielded enclosure with a focus on emissions from 30 MHz to 3 GHz.

The Goal: Buy, rent or make the right tools for pre-compliance testing.

The Goal: Make your pre-compliance test setup as close to the MIL-STD-461 setup as possible.

Caution: RF current probes have some limitations that should be considered when using them. The main disadvantage of RF current probes is that they have a relatively low maximum frequency, though some affordable current probes can operate at 750 MHz or higher. Another disadvantage is that they are sensitive to the position on the harness, since the currents will form standing waves with valleys and peaks. A third disadvantage is that they measure the current, and this needs to be converted to an electric field with an estimation.

The Goal: Measure the radiated emissions coming from common mode currents on the cables and see if more filtering or shielding is required.

The Goal: Measure the radiated emissions coming from the electronics and the cables and identify required fixes before moving forward with testing.

If the steps above seem daunting or you run into problems along the way, then please reach out to EMI Sleuth for help in closing the analysis and getting the unit passing.